This is a guide on how to position your motor so that there is low chance of it unlatching from the lens during your shoot.

Back when I started using a wireless follow focus I always found that my motor would pop off when calibrating or during really fast pulls. It bugged my why It would only sometimes happen. I even started to zip tie or use rubber bands to hold the motor to the lens.

Most motors have two clamps, one for the rod and the other to position the motor relative to the rod. In the motor below we have a 19mm rod clamp with a 15mm rod adaptor. There is a dovetail style clamp to position the motor.

The dovetail style clamp on your motor is very strong and is almost never the weakest link when a motor comes off unintentionally. Unless you’ve forgotten to re-calibrate a lens and go past the end stop of a lens!.

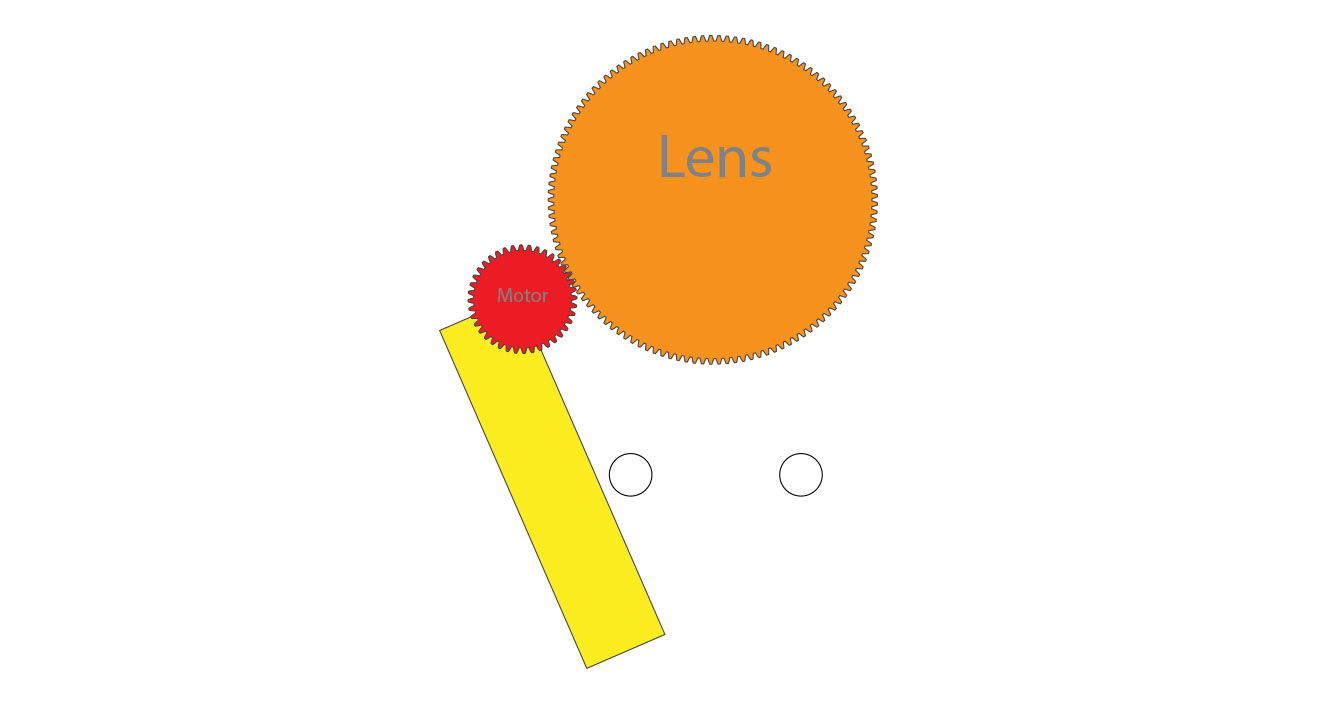

Here is a classic example of a motor on a lens using 15mm lightweight support (LWS)

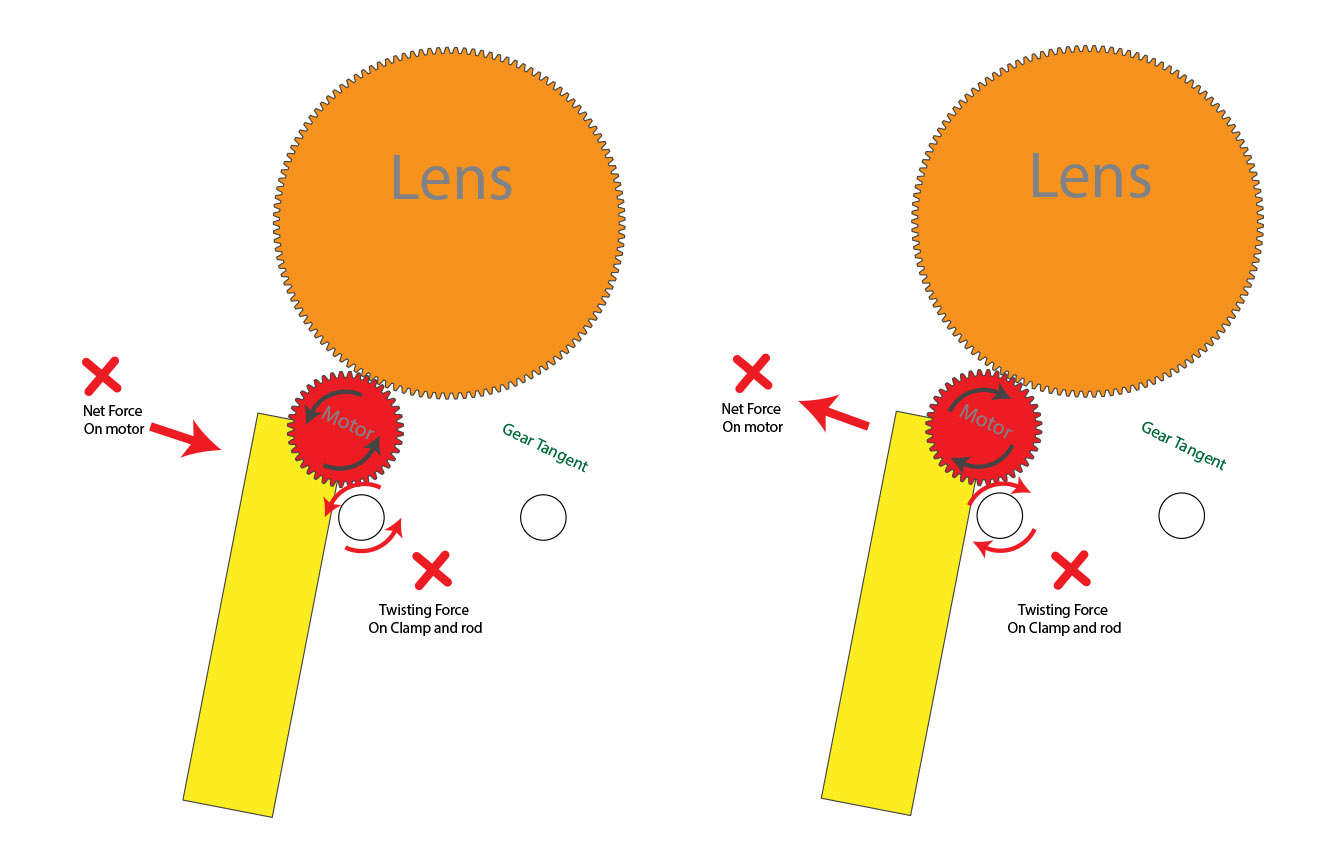

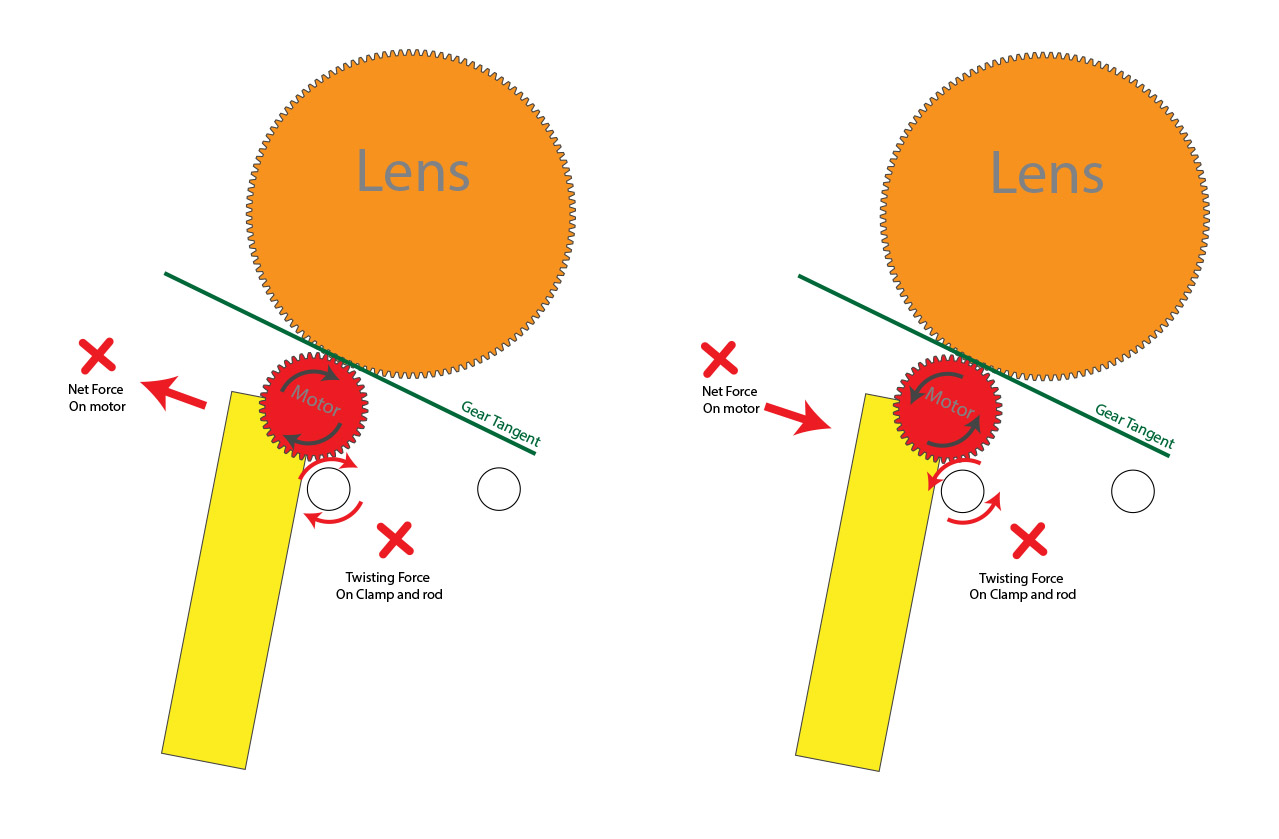

In the extreme example below the motor is placed too high and is forced off the lens during calibration. This occours when calibrating in the counter-clockwise direction and it hits the hard stop. Similarly the motor below is placed too low and the motor is forced off the lens during clockwise calibration

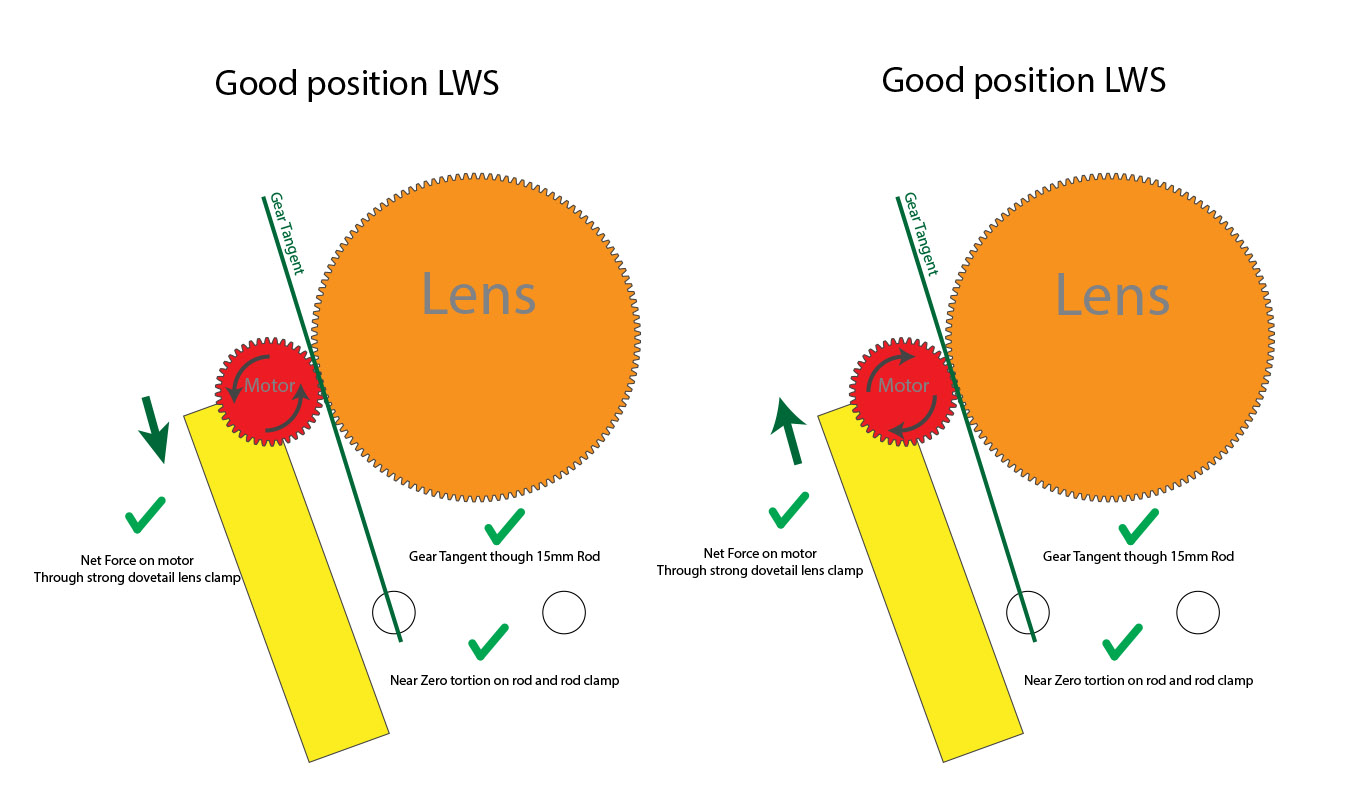

If you draw a tangential line across where the two gears connect and ensure that it goes though the 15mm rod the motor is mounted upon you will find that it will not come off in either direction as all the force goes though the strong dovetail clamp.

If we use apply the same technique to the earlier examples we can see that it doesn’t cross the rods.

Studio Rods

When using studio rods with a small motor you may find that you can’t get a good position due to the motor length.

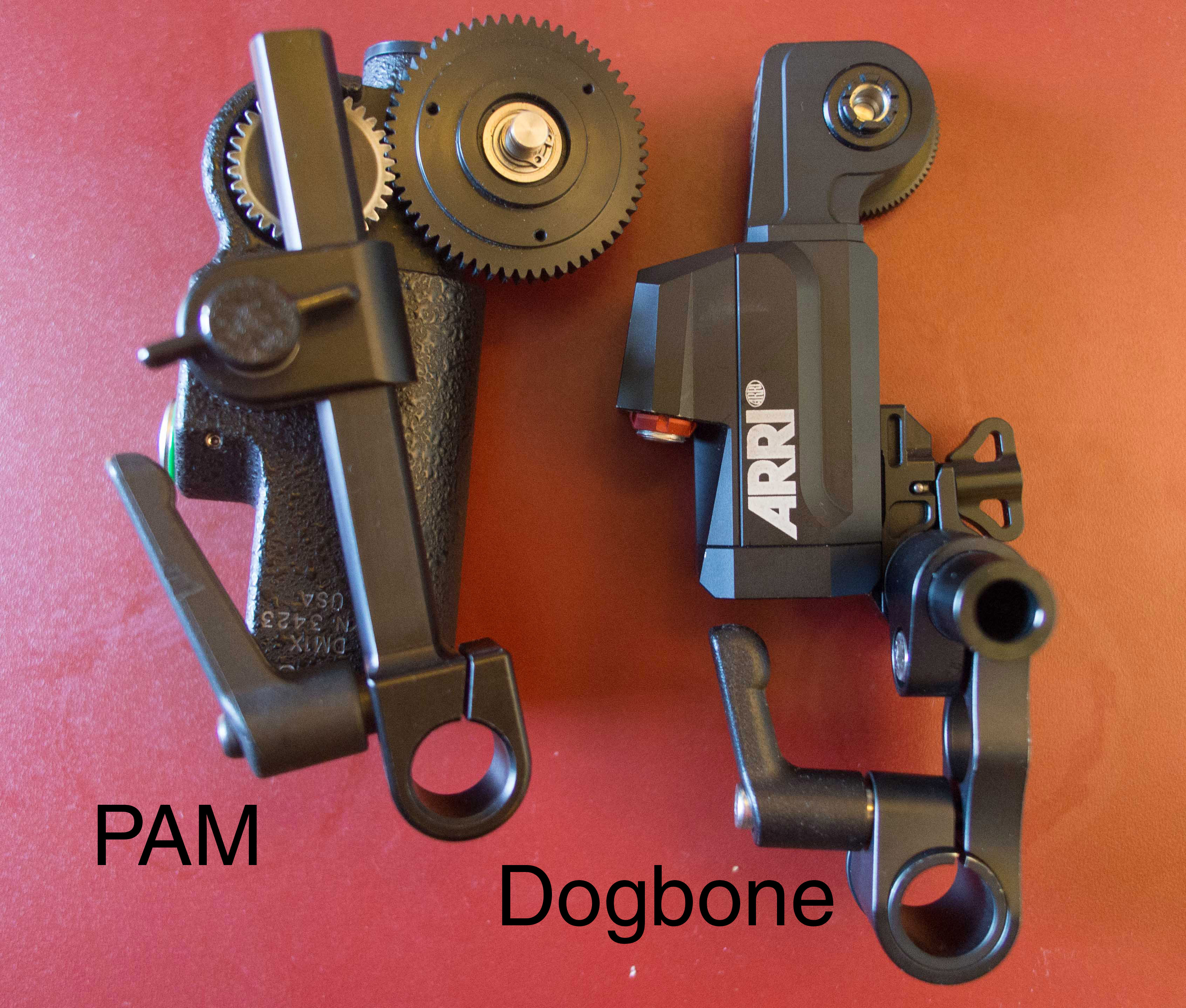

To solve an issue like this use a Dogbone or a PAM mount for your motor.

Mount as below. Making sure the tangent goes though the rods noting that the rosette style clamp on the PAM does not need to pass through the tangent as it is very strong and will not slip.

Don’t forget that adding a lens support (that holds your lens from both up and down motion) and using steel instead of aluminium (or carbon fiber) rods can help stiffen up the rig significantly. When your rig has flex the motor can bend the lens which can increasing your chances of slip, decrease accuracy and even change your framing every time you change motor direction. This occurs most often at the end stops. On top of this swapping to a 19mm rod setup can also help immensely with stiffness.

Thank you.

LikeLike